The Hidden Hero of Hardware: Test Engineering and Paul McDonald

More engineers should spend time building things with their hands. Not because it makes them better designers—but because it makes them better communicators.

If you’ve ever worked on a hardware product, there’s a moment of truth that comes after the prototypes and before the shipments—when someone has to make sure the damn thing works.

And that someone, more often than not, is a test engineer.

Paul McDonald is one of the best I’ve ever spoken with. He doesn’t just build test systems. He bridges design with deployment, verification with business risk, and theory with brutal, real-world limitations.

“Test engineering is the gap between every product design and full-scale manufacturing,” he told me. “It’s the gateway between an idea and making it real—and making money off of it.”

That might sound utilitarian, but Paul’s work at companies like Reliable Robotics, Boeing, and SpaceX reveals a mindset that’s deeply thoughtful. It’s less about polish and more about what’s practical—and what keeps a plane in the air or a certification process moving.

The Real Discipline in Moving Fast

“Build early. Build often. Then look at what breaks.” — Paul McDonald

That’s how Paul frames his process. Not as a rejection of rigor, but as a rebalancing. In his view, most teams wait too long to confront reality. Simulation is helpful, but physical builds are decisive.

“There’s always a reason not to build. The footprint isn’t perfect. The vendor’s quoting long lead times. But the second you have something you can power on—even if it’s a rough prototype—you start learning in a way no spreadsheet or Jira task will ever give you.”

This mindset echoes across the series. As Quilter CEO Sergiy Nesterenko put:

“If you’re not validating your assumptions on real hardware within the first sprint, you’re already behind. Everything else is a guess in formalwear.”

It’s not about speed for speed’s sake. It’s about reducing uncertainty with intent.

Test Systems Are Where Theory Meets Deadline

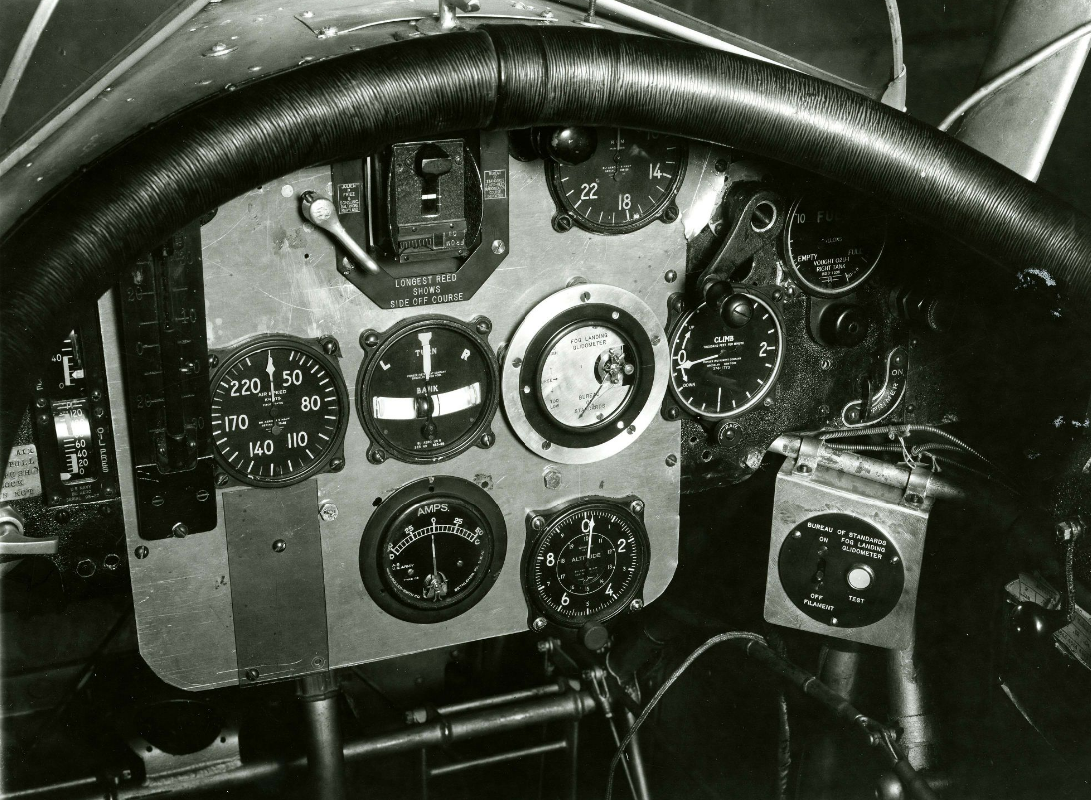

Paul’s current work centers around test equipment for autonomous flight systems. Reliable Robotics is outfitting Cessna 208 Caravans with an auto-flight system that aims to safely enable fully autonomous cargo flights. It’s a big deal. But it’s the test systems behind the scenes that validate every piece of hardware, every connector, every protocol.

“You’re not just designing for function,” Paul explained. “You’re designing for manufacturability, for maintainability, for the ability to rework things quickly if something breaks.”

These systems must validate performance across mission-critical interfaces—often under compressed timelines and with tight certification criteria. They also need to be air-gapped and modular. Why? Because unlike traditional software environments, these systems can’t rely on cloud tools or continuous deployment. One corrupted test result could delay a $10M flight program.

He summed it up simply: “The code can’t fail. Not just because it’s annoying—because it could be dangerous.”

The Art of Minimalism in a Maximalist World

One of Paul’s biggest epiphanies was realizing he could avoid custom circuit boards almost entirely. “I can eliminate the need for most PCBs in test equipment by thoughtful cabling and harnessing,” he said. “It takes at least a month off the design cycle.”

It’s not just about cutting corners. It’s about designing test systems that are more adaptable, more serviceable, and ultimately more valuable over time. Circuit boards lock you into a fixed routing model. But if the DUT (device under test) changes—and it often does—you’re left waiting for a redesign and a fab run.

“That kind of inflexibility breaks projects,” he said. “You can’t test fast enough to keep up with design iterations.”

Paul instead advocates for standardized connector systems, modular breakout boxes, and BOMs optimized for supply chain resilience. “If your cables use the same part number pins across multiple connector types, you can stock and service with less inventory. You can troubleshoot faster. You keep planes out of the dirt.”

That last phrase stuck with me. It captures what matters in test engineering—practical outcomes. Not elegance. Not cleverness. Just systems that work, are safe, and can be debugged under pressure.

Where Communication Meets Reality

Paul’s career has required him to constantly translate between stakeholders—engineers, technicians, managers, FAA inspectors, and contract manufacturers. Each one speaks a different language, and many come with their own assumptions about what test systems “should” do.

“I’ve worked with brilliant people,” he said, “but some of them have no idea how much effort goes into validating something well. Especially if they’ve never built it themselves.”

His workaround? Write it down. Build instructions. Create repeatable processes. Make diagrams. Show what matters. And when people still don’t get it, find ways to help them connect with the reality of the system.

It’s not always easy. “You spend as much time explaining the compromises as you do building the test rig,” he told me.

Sometimes that means telling a designer that their beautiful new revision requires completely redoing the entire test rack. Sometimes it means helping a technician swap out a harness with only partial documentation because the previous version is obsolete. And sometimes it means explaining to management why a slipped schedule wasn’t a failure—but a necessity.

Leadership That Ships

We asked Paul what qualities he looks for in a lead hardware engineer. His answer was immediate: clarity and tempo.

“I want to see someone who can reduce ambiguity in the room—and keep the build moving forward.”

Leadership, in this context, isn’t about escalation paths or process frameworks. It’s about understanding the interplay between design, manufacturing, testing, and product constraints—and making tradeoffs that reflect reality, not just aspiration.

Carolina Hubbard, who leads interdisciplinary teams in electromechanical systems, expanded this further:

“Designing the hardware is the easy part. Designing the communication and trust structures around it—that’s the real challenge.”

The best teams don’t just ship—they scale. Because their decision-making gets better under load.

The Myth of the Perfect Design

There’s a quiet honesty in how Paul talks about design. He knows things will go wrong. He just plans for it.

“No design is perfect,” he said. “You build the best version you can, you test it, and then you iterate. That’s the job.”

It’s a philosophy shaped by experience. Test engineers don’t have the luxury of believing in ideal outcomes. They see what happens when assumptions fail—and they carry those scars into the next project.

He also cautions against the fantasy of fully automated design systems. “Every part of a test system still requires human judgment. The idea that you can script your way to perfection is just wrong.”

But he’s not cynical. He’s hopeful—in the practical way that great engineers are. He believes in process, preparation, and building for resilience. “If I can shorten the failure response cycle by even a few hours, I’ve done something meaningful.”

Speeding up hardware design is no longer just about smart component choices or clean schematics. You can hack together with AI-driven PCB design tools to change the game. The fundamentals remain: start with a well-defined schematic and a strong idea of what you need mapped out, then let assisting engines take care of the iterative and exploratory work so that you can focus on the hard work. This means fewer design spins and a much faster path to a manufacturable board.

Pair AI design with reference templates from component manufacturers to save time on proven layouts. Use machine learning–powered DFM checks to catch manufacturing issues early, ensuring your first prototype is as close to production-ready as possible. Collaborate with your fabrication and assembly partners and feed their constraints directly into AI tools. This ensures the design is optimized for both speed and scalability.

Moving from concept to prototype fast is often the difference between hitting a market window and falling behind. If you want to speed up your circuit board design, start by using all the tools at your disposal. But design for test from the start. Add test points and ensure you can validate the prototype as soon as it is built. Fast design is meaningless if the first board fails basic checks.

Thoughts on Tooling, Software, and Working Hands-On

Paul doesn’t pretend that tooling is perfect. He’s hacked Altium to export wirelists. He’s built his own configuration libraries for harnesses. He’s worked without access to the high-end software platforms that large OEMs rely on—and made it work anyway.

“I’ve done more with PDFs and spreadsheets than most people realize is possible,” he said.

But the heart of his approach is still hands-on. Paul went back to vocational school after earning two bachelor’s degrees—just so he could learn how to rivet panels, repair airframes, and understand what technicians actually face.

That experience has made him a better systems thinker. It’s also made him a better collaborator. “I work with interns, junior engineers, techs who want to do more than desk work. And I train them. Because someone trained me.”

He believes that more engineers should spend time building things with their hands. Not because it makes them better designers—but because it makes them better communicators.

Why Test Engineers Matter More Than You Think

Test engineers rarely get the spotlight. They’re often seen as secondary, a footnote between design and delivery.

But that’s a mistake.

Test engineers like Paul are the people making sure your rockets launch safely, your planes don’t fall out of the sky, and your production lines stay on schedule. They build the invisible systems that validate the visible ones.

They know the difference between “working” and “verified.” Between “good enough for now” and “ready for certification.” Between building for a prototype and building for a thousand units under budget pressure.

Most importantly, they know how to translate. Between design and test. Between software and hardware. Between business goals and engineering reality.

That translation is the real magic. And Paul McDonald is one of the best at it.

Hardware Rich Development is a series from Quilter.ai that explores what it means to build high-integrity hardware in a fast-moving world. If you’re leading an engineering team or driving technical decisions in your organization, and you’d like to share your insights, reach out.

We’re building a community around better hardware thinking.