Renovelo x Quilter

Renovelo used Quilter's automated PCB design software to explore 32 revisions in 2 months and deliver a "flawless" prototype on the first try.

Meet Jeff 👋

Jeff is the founder of Renovelo, an automotive software company that provides vehicle telematics and tuning software to luxury car owners who want to customize their vehicles' behavior and performance.

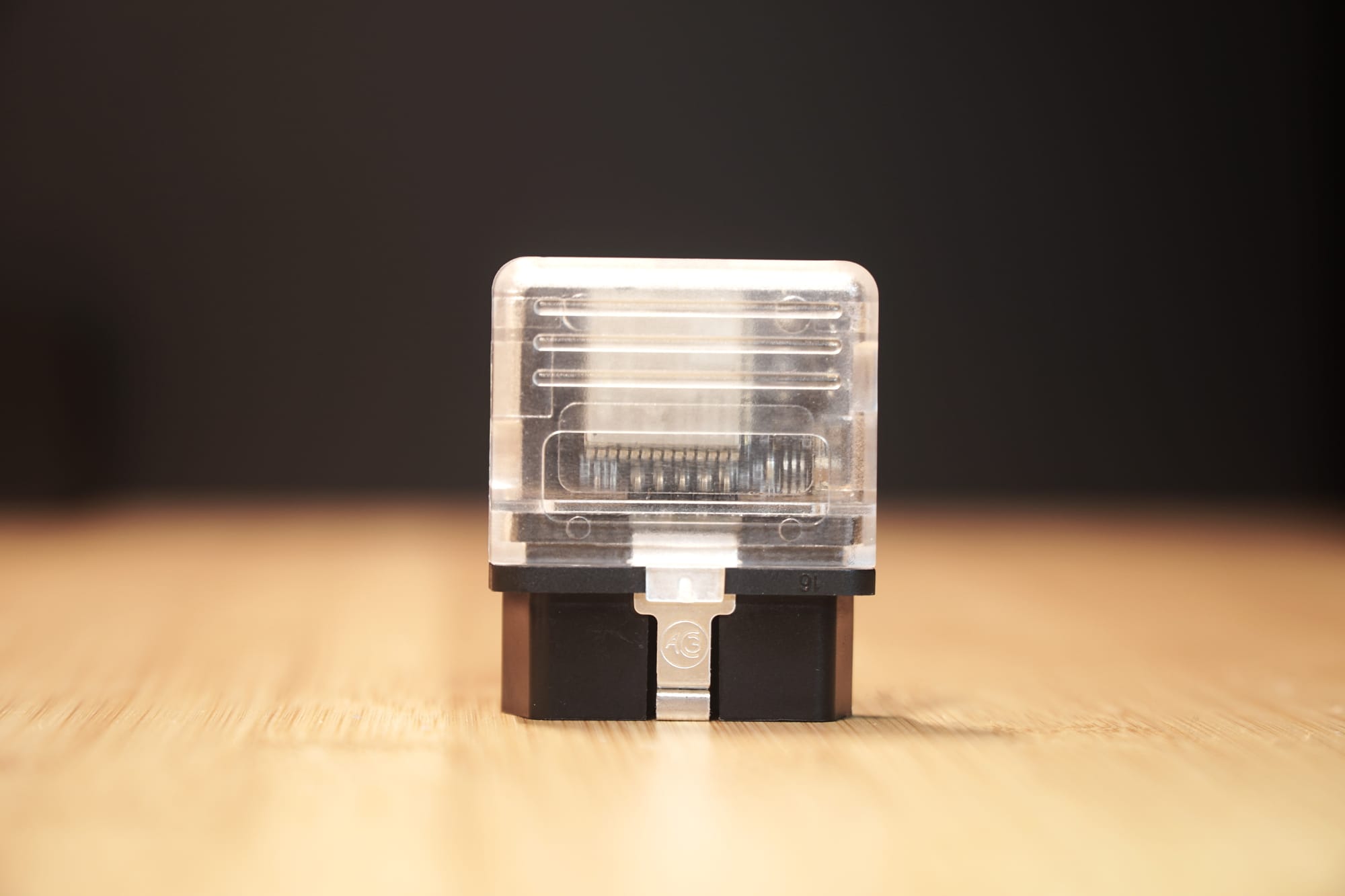

Jeff used Quilter to develop “ByteFlasher,” a new, simplified version of his automotive tuning suite that includes a custom-designed OBD2 hardware accessory to wirelessly receive vehicle customizations from his app and program them to the vehicle—no cables required.

The challenge

Although he had already built a functional breadboard prototype of ByteFlasher, he knew that translating it into a production-ready PCB design would take a lot of time and expertise that he didn't have.

Jeff has a lot competing for his attention. Between developing his flagship software suite, building a new mobile application, standing up a marketing site, and running sales and support for new and existing customers, Jeff knew that spending weeks struggling through a PCB layout that might contain mistakes wouldn’t be the best use of his time.

He planned to outsource the design but knew that building a prototype would cost thousands of dollars and might take as much time to outsource as to design it himself.

"I was scouring LinkedIn for days trying to find a PCB designer in the automotive sector who also had ESP32 experience. I was this close to reaching out...and that's when I found Quilter."

The solution

By using Quilter’s AI-powered, physics-driven PCB layout software, Jeff was able to:

1/ Build it right the first time.

"Not only did [Quilter] increase my confidence, I did it...it's here! Everything absolutely works on it perfectly. It passed all my bench tests, all my vehicle tests...I'm not changing anything."

Initial prototypes can cost thousands of dollars and weeks of time to build, yet often contain human errors that prevent them from working as expected. Quilter helped Jeff avoid these pitfalls and enabled him to create a fully functional prototype on his first try.

2/ Use the time he saved to build his business.

"I was able to get one job out, and then I could go work on firmware, or website, marketing, mobile app, whatever..."

Iterating with Quilter allowed Jeff to invest his extra time into improving his software and marketing his new product.

3/ Get finished layouts, faster.

"I submitted a layout and, it worked – I got a layout back in an hour and a half! Yeah...I was blown away."

In less time than it would have taken him to source and onboarding a contract PCB designer, Quilter generated multiple variations and iterations of his board that he could start iterating with.

The results

Jeff used Quilter to:

- Generate an initial set of working designs

- Explore different form factors and shrink the physical size of his product

- Quickly respond to the dynamic availability of different production ICs

- Explore the impact of different placement and routing strategies on cost, manufacturability, and performance

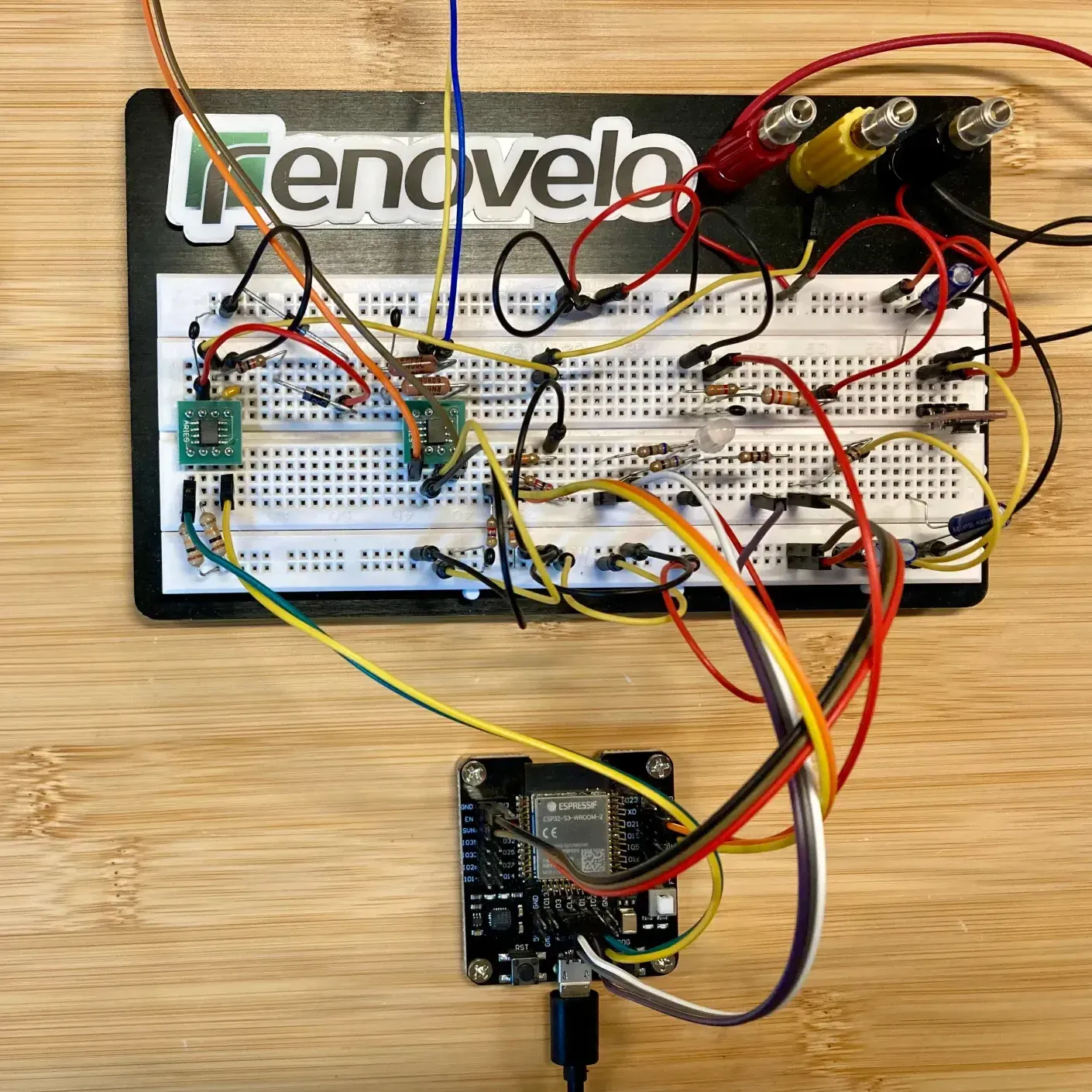

Here are some photos of ByteFlasher – imagined by Jeff and designed hand in hand with Quilter.

Jeff's ByteFlasher prototype – designed with Quilter – in action

Start building with Quilter

"Now I know I've got ChatGPT to help me with my firmware when I get stuck on a section of my firmware, and I've got Quilter for when I get stuck on a section of my PCB design."

Quilter is already changing how engineers at some of the world’s most innovative hardware organizations design and build electronics.

Are you ready to learn how you can use Quilter to save valuable engineering time and iterate faster than ever? Schedule your demo today!