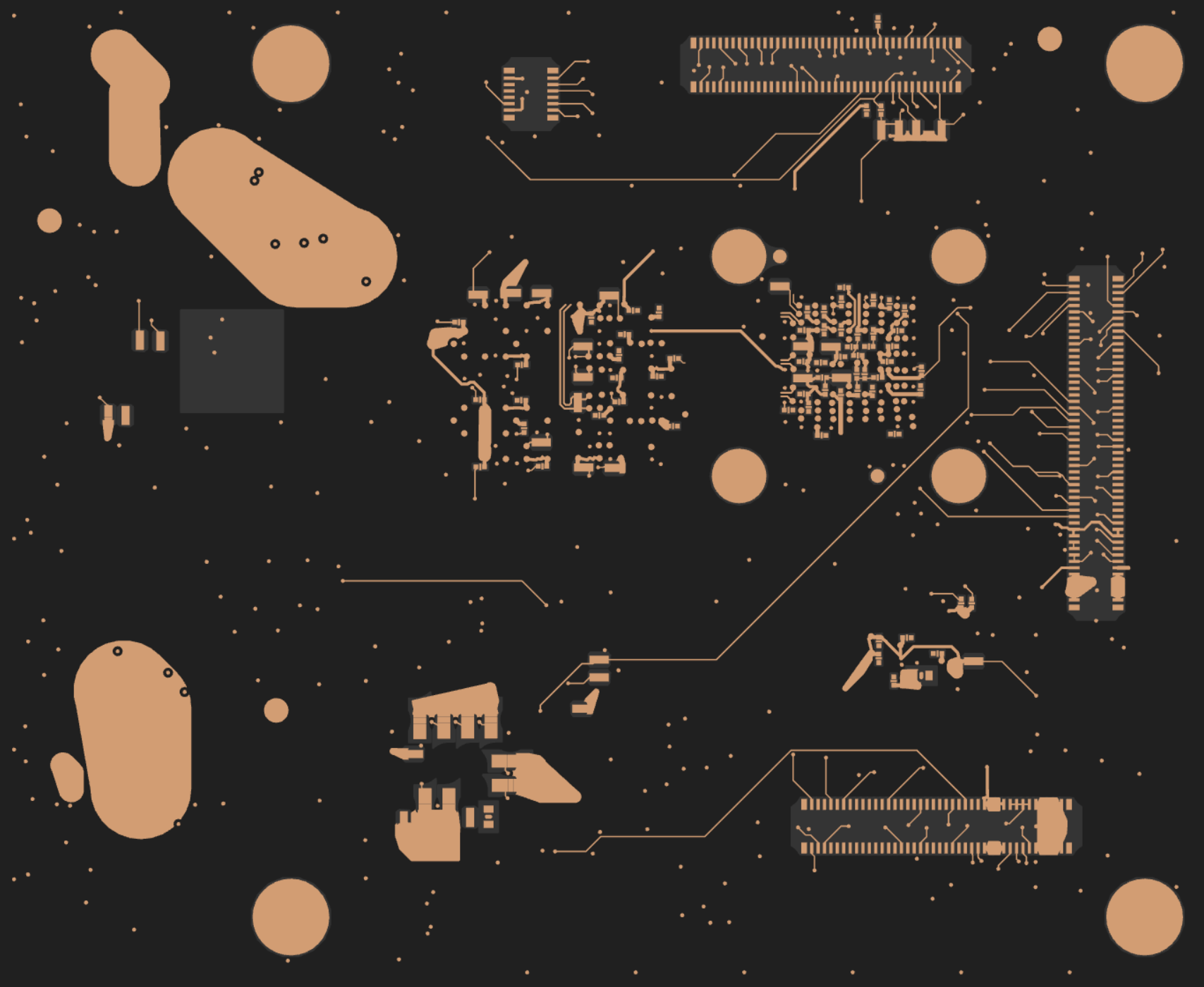

Quilter can now create power pours!

If you’ve ever lost hours drawing and fixing copper pours by hand, this update is for you.

The only AI PCB design software that automatically generates copper fills for more reliable power delivery in a fraction of the time.

Does this sound familiar: You're rushing to get a board out the door, only to lose time dragging polygons, resolving DRC errors, or wondering if your pour is even valid.

For something as essential as power delivery, why is this still so manual?

Engineers Shouldn’t Be Drawing Polygons by Hand

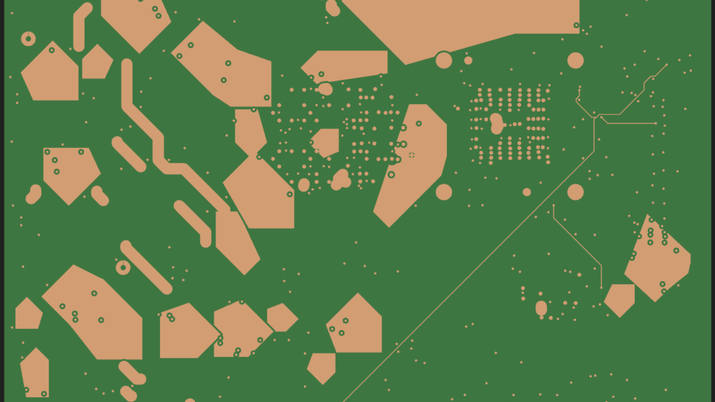

Power pours, also known as polygon pours, are large copper-filled areas connected to a specific power net. They provide a low-impedance path for current, helping to reduce voltage drop and minimize heat generation.

When designed well, they make boards more reliable. When done poorly, they can lead to failed tests, additional rework, and ultimately missed deadlines.

Power pours are critical, but the tools to create them haven't kept up. And we’ve all tolerated this status quo for too long.

Quilter is the only AI-powered PCB design software that automatically creates power pours.

Quilter Does the Tedious Work for You

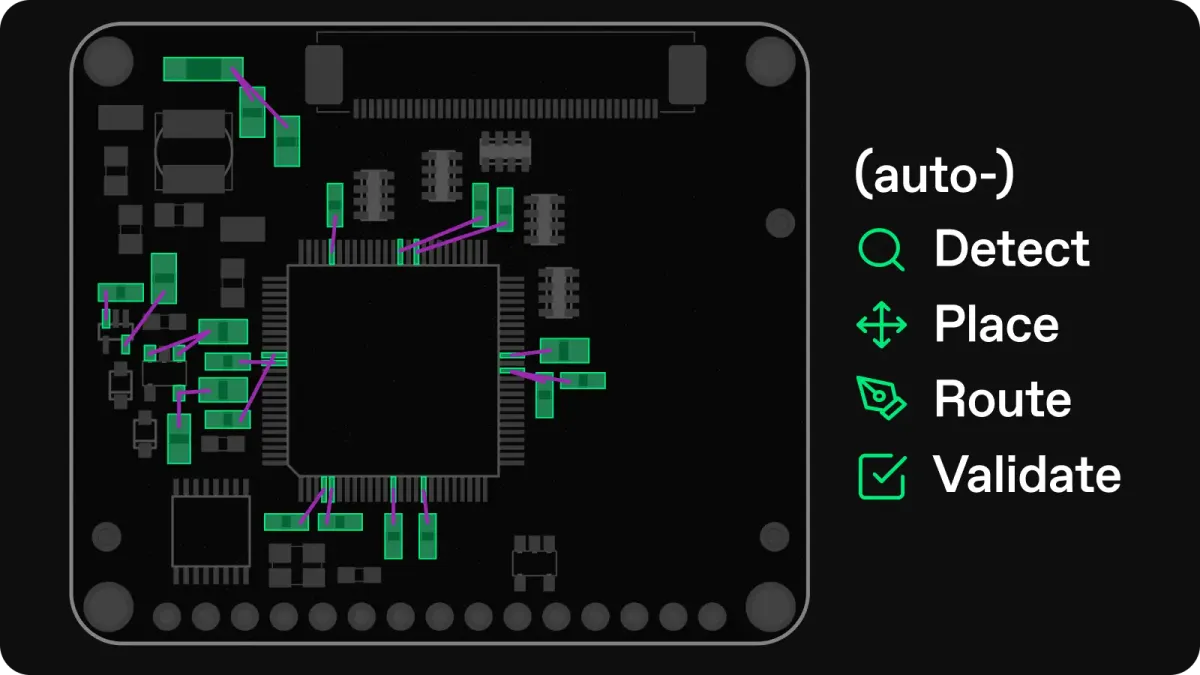

Power Pours are fully integrated into Quilter. Here's how it works:

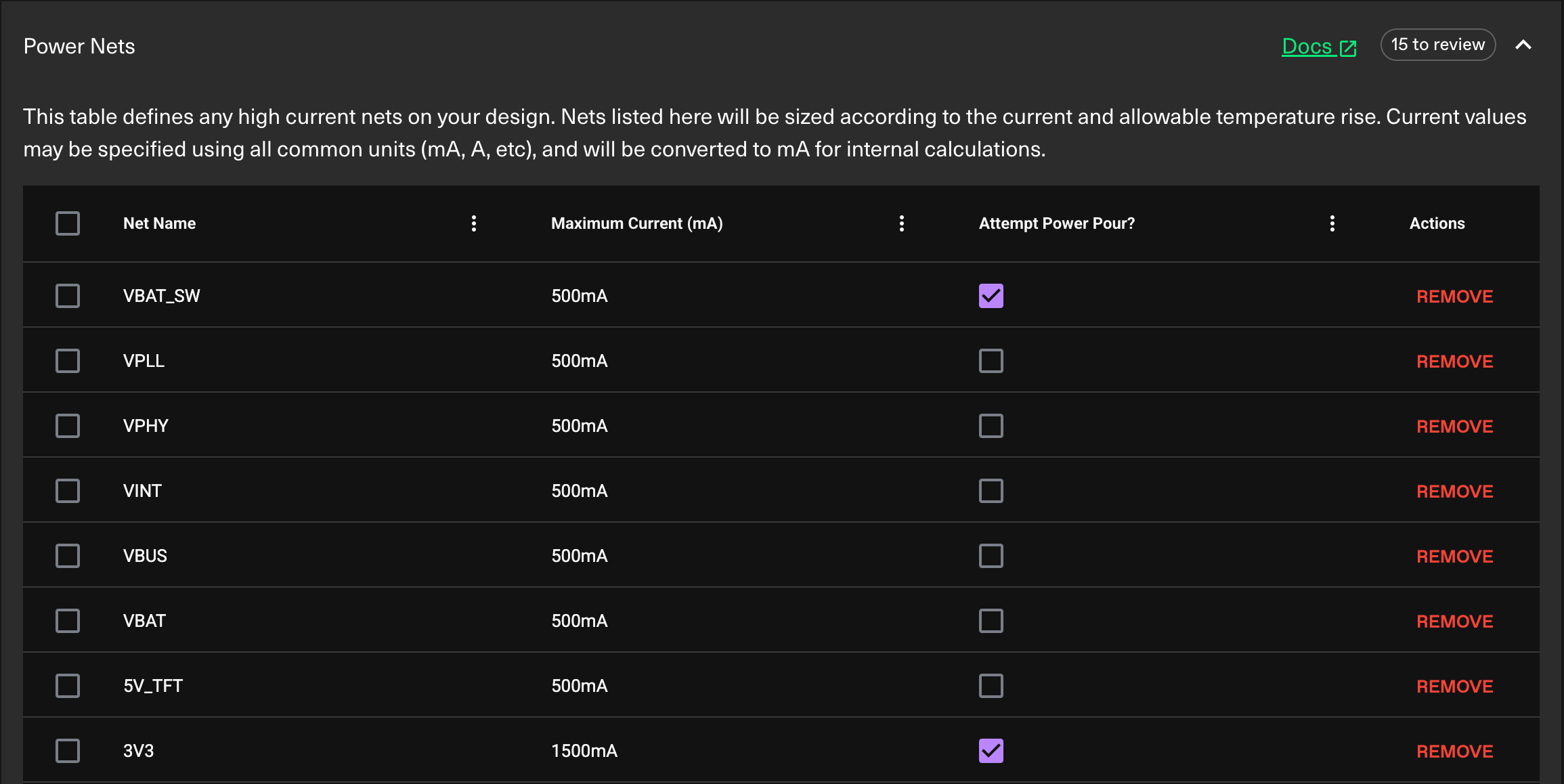

- Smart Net Detection – Quilter automatically detects likely power nets based on common naming patterns (e.g., VCC, 3V3, 5V) and netclasses and surfaces them for review to help you move faster without missing critical nets.

- Selective Pour Control – You decide which nets should receive a pour. Quilter's suggestions accelerate setup, but you retain control: override any default, add custom nets, or skip pours entirely to ensure only the right nets get power pours.

- Placement Optimization – Quilter adapts component placement to improve pour success. The placer engine rotates and clusters parts on selected power nets to reduce fragmentation and increase copper continuity, making it more likely the resulting pour will connect pads cleanly without manual correction.

- Automatic Copper Generation – Once placement is complete, Quilter generates a filled copper region connecting pads with solid copper while respecting spacing rules, component keep-outs, and routing constraints. It replaces individual routed traces with pours that require no manual drawing or repouring.

- Physics Rule Checks (PRCs) – Quilter's physics rule checks (PRCs) run on Power Pours for trace width and current-carrying capacity to help ensure a manufacturable copper width based on the expected current. What used to take 20 clicks and two rounds of checks is now completely automated.

It all happens automatically as part of standard candidate generation without manual pre-work or post-process cleanup in your CAD tool.

More Boards. Less Baggage.

In traditional tools, polygon pours are a manual and time-consuming task. In Quilter, it's a checkbox.

- No More Manual Polygon Work: Traditional tools require designers to manually draw and manage copper pours, including clearance settings and thermal reliefs. Quilter now handles this for you, saving time and eliminating a common source of layout frustration.

- Broader Design Coverage: By automatically generating pours during layout, Quilter expands the range of boards it can fully automate, including test boards with large ground planes, analog designs, and mixed-signal layouts that previously required hand-tuning.

- Faster First-Pass Success: Quilter optimizes placement and pour generation simultaneously, improving layout quality and reducing the number of iterations needed to produce a working board.

Start Using Power Pours Today

If you’ve ever lost hours drawing and fixing copper pours by hand, this update is for you. Quilter now handles that work automatically—delivering better power delivery, fewer layout errors, and a faster path to a working board.

- Already Using Quilter: Log in and try Power Pours now to complete your next board before the end of the day.

- Ready to Get Started: Sign up free and see what fast, physics-driven layout feels like.

You’re Shaping the Future of Hardware Design

We continually test new capabilities based on your feedback, with many of our most impactful features emerging directly from engineers like you.

Have thoughts? Send them our way. You help shape what we build next.

Our Last Product Updates