Just Ship It: Lessons in Grit, Test, and Team from Paul Robinson’s Hardware Odyssey

That polymath tendency—the willingness to learn a bit of everything—is often the best preparation for a future no one can predict.

Roles:

Director of Manufacturing Software & Test, Apple; Hardware Test Lead, Amazon Focus Areas: Manufacturing Test, Product Delivery, Team Management, Design Resilience

Key Takeaways

- Test time is money. Every second of factory test time comes at a cost, and smart teams learn when to spend and when to save.

- Relationships are engineering tools. The best test systems were built not just with logic and code but through trust and human alignment.

- Leadership is not control. Great managers don’t outperform their teams—they build teams that outperform them.

- EQ matters more than ever. The enduring gap in engineering is emotional intelligence, not technical skill.

The Backend is Where It Gets Real

As the host of Hardware Rich Development, I talk to a lot of hardware veterans. Most of them are process-minded, fiercely technical, and deeply pragmatic. But every once in a while, someone comes along who’s seen enough, done enough, and reflected enough to speak with a rare kind of clarity. Paul Robinson is one of those people.

Paul’s not just a test engineer. He’s a living blueprint for what execution looks like over a thirty-five-year career spent mostly behind the scenes—writing manufacturing software, building diagnostics tools, designing systems that most people will never see, but everyone benefits from. His career included decades with Apple, a stint at Amazon’s Lab126, and countless nights on the phone with China or Ireland ensuring products shipped on time.

And now, newly retired, he’s touring Europe with his wife and finally taking the vacations he never could.

What follows is not just a summary of our conversation. It’s a meditation on what his experience taught me—and what it should say to the next generation of hardware engineers and builders.

Falling into Test, Rising with Curiosity

Paul didn’t aim for a career in manufacturing and test. Like many engineers from his era, he got there by following his curiosity. He entered college to study architecture but was convinced by a new professor to try computer engineering instead. That pivot sent him into early roles building communication frameworks for military drones—systems that, remarkably, may still be in use today.

From there, he got a call from Apple. A test engineering job.

“I didn’t even really know what test engineering was,” Paul said, “but I had a mix of electrical and software experience, and I fit.”

This is something I hear a lot: the best technical careers are built by people who know just enough in multiple domains. That polymath tendency—the willingness to learn a bit of everything—is often the best preparation for a future no one can predict.

Test as Commitment, Not Afterthought

Paul’s ethos around test was shaped by Apple’s culture. At Apple, test isn’t a formality at the end. It’s the make-or-break stage of the product lifecycle.

“You ship. No matter what. That was the mindset,” he told me. “We didn’t cut features. We just made it work.”

One of the more vivid stories came from the Apple Watch. A new sensor needed exact temperature calibration in the factory. The first approach failed. Paul and his team ended up calibrating the watches by sealing them in Ziploc bags and dipping them into circulating ice water. It was inelegant. It was absurd. It worked.

As someone who’s spent my career helping companies tell their technical stories, I love this example because it gets at the real narrative of engineering: the moment when ingenuity meets constraint, and the team finds a way. Paul’s story was full of those moments. From repurposing sensors to balancing cost and precision, it was clear that test isn’t just verification. It’s the point of proof.

The Cost of Test Time, the Value of Urgency

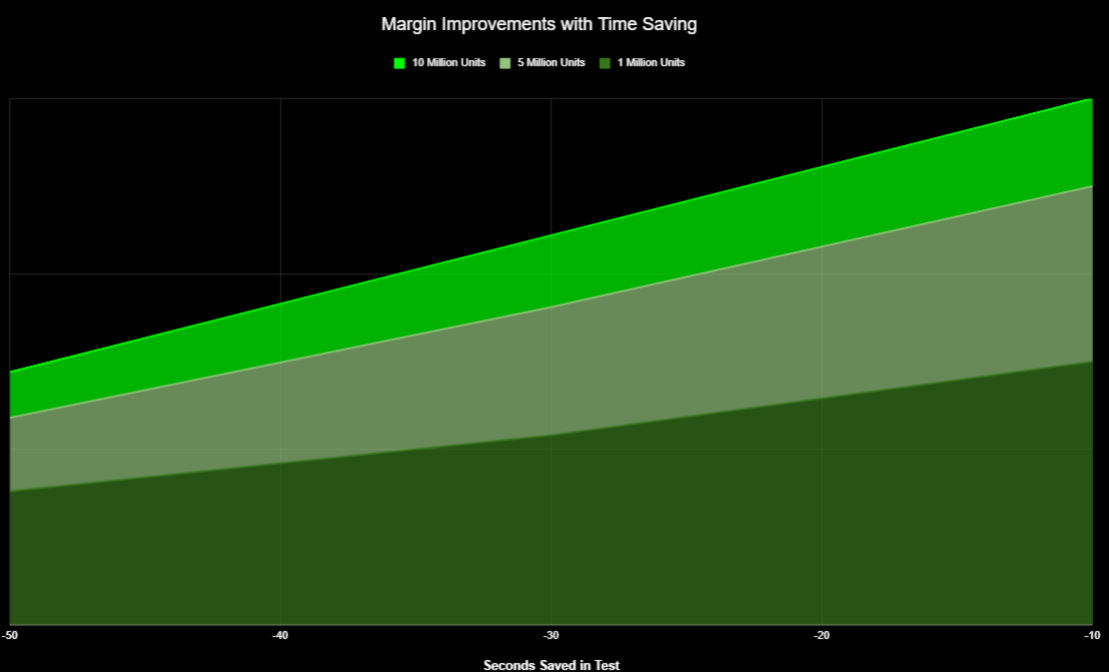

“Test time is money.”

That was one of Paul’s mantras, and it hit home. In a factory, every second matters. A minute of test time means test equipment, operators, energy, and throughput. And yet, in the early phases of a product cycle, you spend lavishly—just to be sure the product works.

Later, sometimes in the next generation, you optimize. You cut the test time down from sixty seconds to ten. That’s how margins are made. It’s one of the best examples I’ve seen of strategic debt: do what’s necessary to launch, then invest in efficiency after.

In our conversation, I realized how often we mistake optimization for progress. But Paul reminded me that the real progress is getting the product to customers, functioning as intended, when you said you would.

Leadership Is Letting Go of Ego

One of the most human moments in our interview came when Paul told me about his early management days. Frustrated with a team member’s buggy code, he rewrote it himself over a weekend. It worked better. But it also fractured the relationship.

“I learned something then,” he said. “As a manager, your job isn’t to be the best coder. Your job is to build a team that’s better than you.”

That line stuck with me. It’s the kind of insight you don’t get from management books. You get it by screwing up, making someone feel small, and realizing that technical excellence means nothing if the team doesn’t trust you.

As someone who’s worked on both sides—technical contributor and team leader—I’ve seen that dynamic play out again and again. Leadership in engineering isn’t about control. It’s about empowerment. You’re not the hero. You’re the multiplier.

When Great Hardware Meets Bad Product

Not every story had a happy ending. Paul worked on Amazon’s ill-fated Fire Phone—a product with solid hardware and a deeply flawed user experience.

“We all knew it wasn’t going to do well,” he said. “We were sideloading Android onto our test phones just to make them usable.”

I’ve always believed that the best technical teams are also capable of seeing the product. Not just the internals. Not just the bill of materials. The full experience. Paul knew that. He even used the Fire Phone as a cautionary tale when mentoring junior engineers.

“Just because it worked yesterday doesn’t mean it works today.”

That principle is evergreen. It applies to tools, to UX patterns, to internal processes. And it’s the kind of wisdom that separates maintainers from innovators.

Late Lessons on AI and the Tools That Wake You Up

In his final year before retirement, Paul found himself resisting large language models. His boss asked for ideas, weekly. He pushed back. Until one of his engineers started applying LLMs to factory data, revealing insights that were impossible before.

“It was amazing. All of a sudden, we could ask real questions about the data.”

The turning point was the demonstration rather than the technology. The peer-to-peer moment of clarity, that brotherhood.

As a marketer, I’ve seen this in a different light. No one is convinced by slides. Everyone is convinced by impact. Show the thing. That’s how minds change.

What Engineers Lack—and Always Have

Despite all the technical complexity in his career, Paul ended with a very human diagnosis of what’s still missing in most engineering organizations.

“There’s no shortage of good engineers. What’s missing is EQ. Communication. Seeing the big picture. That’s always been the gap.”

It’s something I keep hearing from the best engineering leaders. And yet, we still don’t train for it. We focus on new languages and tools, but we don’t reward the ability to build consensus, manage conflict, or explain hard things in plain language.

That’s the engineer of the future. It’s also the engineer of the past. The ones who stood out always had range.

Final Thoughts: The Gratitude of Someone Who Shipped

Paul’s career wasn’t just about shipping hardware. It was about building teams, growing through mistakes, working too many hours, and finally learning to say yes to the rest of life.

His final shout-out went to his wife, Grace, who raised their kids while he spent years on calls, in factories, or lost in code.

“I was never home. And when I was, I wasn’t present. But she stuck with me.”

In the end, Paul’s story isn’t a perfect arc. It’s not a clean narrative of success. It’s real. It’s messy. It’s human. Which is exactly what makes it valuable.

This is the kind of engineering I want to showcase on Hardware Rich Development—the kind where code, people, and consequence all collide. The kind where the people behind the product are just as impressive as the product itself.