Design with Your Hands, Lead with Your Eyes — Nancy Smith and the Grounded Future of PCB Design

There’s no hierarchy. We all just want to build the best product.

If you ask around long enough in hardware circles, you’ll hear whispers about the “lost generation” of board designers—folks who came up taping rubylith, laying copper by hand, debugging with an iron in one hand and a datasheet in the other. People like Nancy Smith, who not only kept pace with the evolution of electronic design, but somehow got better with every tool, every revision, every new expectation dumped on their desk.

Nancy Smith is a senior PCB designer working with Pacific Design Engineering. When I chatted with Nancy, I wasn’t looking for nostalgia. I wanted perspective. I wanted someone who could tell me without the buzzwords or VC gloss what’s actually happening to PCB design today.

What I got was something better: a reminder of why I got into hardware in the first place.

The Discipline of Hands-On Design

“I’ve soldered boards, debugged prototypes, worked in SolidWorks, sourced components, and handled 3D printing—I've done it all.” – Nancy Smith

There’s a quiet kind of confidence that comes from doing every part of the job yourself—at least once. Nancy’s not interested in flexing. She’s interested in fluency.

In an industry increasingly filled with designers who’ve never touched a soldering iron, her perspective matters more than ever. Not because she’s old-school, but because she remembers something we’re too quick to forget:

The best design doesn’t come from abstraction. It comes from proximity.

You can’t simulate intuition. You build it. Layer by layer. Mistake by mistake. Prototype by prototype.

As Paul Robinson put it when we spoke:

“We’ve spent the last decade optimizing design tools to remove friction—but friction is where the learning lives. You have to feel the resistance before you know what you're really designing.”

Cutting Traces, Cutting Excuses

Nancy’s first boards were laid out using rubylith and donut pads—cutting film by hand and placing traces manually on a light table.

“I took a few years off to raise my three kids, and when I came back, everything had moved to computers. I had to relearn the entire process from scratch.”

That adaptability, that reflex to learn instead of resist, is missing in a lot of organizations today. We silo teams by domain, we treat electrical as independent from mechanical, and we onboard junior engineers into workflows that are three layers removed from the product.

Nancy doesn’t accept that. She designs boards like they’re going to break because they will. She pays attention to how they’re assembled, who’s using them, and where they’re likely to fail.

And here’s the kicker: she’s having fun.

“Having someone draw something on a napkin and turning it into a SolidWorks model, then printing it in 3D — that’s a lot of fun.”

The joy is the job. And it shows in her work.

The State of the Board

Let’s be real: the PCB design industry is bloated in some places and starved in others. We’ve got powerful tools, weak mentorship, and too many teams afraid to challenge engineering theater.

“There's a lot of customers out there that don't want to have an impedance controlled circuit board on two layers and you can't do it. So there's different types of things that you have to be upfront with them and say, look, you need to have these certain amount of layers or if this is completely controlled, you might have to have blind or buried vias, which increases the cost. So that kind of stuff needs to be up front before they even start on it instead of saying we'll just make it work. Because then you're into Rev 2 and 3 and 4 and then you're scrapping the whole thing and starting from scratch just so you can pass FCC or EMI or anything else. .” – Nancy Smith

That’s the permission that comes from clarity. The kind of clarity you only get after seeing how bad things go when no one speaks up. When reviews become rubber stamps. When “we’ll fix it in firmware” becomes a punchline for systemic dysfunction.

This is where engineers like Nancy, and Sergiy Nesterenko, shine. Sergiy framed it like this in our interview:

“If your prototype passes validation but still fails in the field, you didn’t build a product—you built a gamble.”

The Necessity of Craft in PCB Design

Printed circuit boards are everywhere. They power the phones in our pockets, the servers that drive the internet, and the satellites orbiting above us. For something so fundamental, the process of designing a good PCB is often reduced to a checklist: hit the clearances, pass the DRC, send it to fabrication, and move on.

But good PCBs do not happen by accident. They are the result of care and craft. That word matters because craft implies more than compliance. It implies skill, attention, and an understanding of how each decision will shape the outcome.

A PCB is not just a green rectangle with copper traces. It is the nervous system of your product. Every design choice has consequences. A poorly thought-out layout can create EMI problems, thermal issues, or manufacturing delays. The cost of fixing those problems is measured in time, money, and lost confidence.

Good boards begin with understanding. Not only of the schematic but of the entire context. How will the product be assembled? What mechanical constraints exist? Where is this board going to live, and how might it fail? Too often, designs are created in isolation inside a CAD tool as if the physical world is an afterthought. That is not engineering. That is guessing.

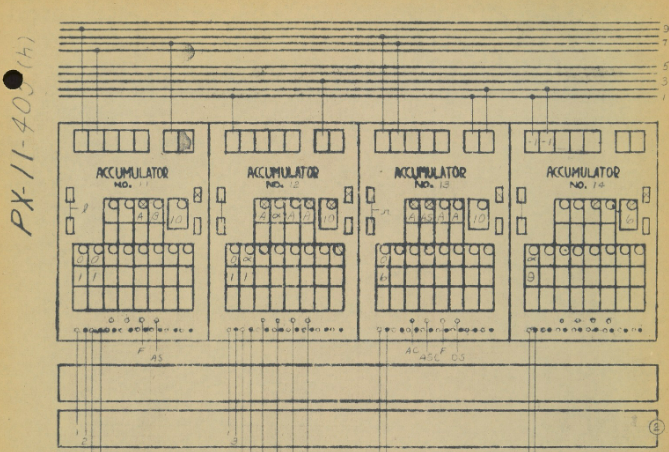

Signal integrity, power distribution, and manufacturability are not extras. They form the foundation of a board that works in real life. Ignoring them creates a stack of compromises that collapse under stress. Controlled impedance is not a suggestion. Neither is thermal relief. These details matter whether you are building a prototype or scaling production.

Collaboration matters too. The best designs come from conversations between electrical and mechanical teams, between design and test engineers, and with the people who will assemble the product. Throwing a file over the wall and hoping for the best is a recipe for rework.

The truth is that the best PCB designers are not just technicians. They are translators who bridge domains and anticipate friction points before they appear. They think about how every trace and every component affects not just function but assembly, testing, and long-term reliability.

Tools are important. So are certifications. But what matters most is the mindset: care enough to do it right. A PCB is not simply copper on fiberglass. It is the skeleton of your product. And if the skeleton fails, nothing else will stand.

Collaboration Without Ego

“There’s no hierarchy. We all just want to build the best product.” – Nancy Smith

Nancy’s team operates like a band—not a bureaucracy. She uses Altium Designer 365 and real-time chat tools to loop in mechanical, software, test, and the customer—in the design process.

This is what modern hardware development should look like: cross-functional, shared context, built on mutual respect not handoff delays and siloed Slack threads.

And this isn’t just better for product. It’s better for people.

We spend too much time in hardware trying to make tools solve cultural problems. But Nancy shows us something different: when the culture is right, the tools get out of the way.

Design by Philosophy, Not Preference

Nancy’s stack includes the standards: SolidWorks, Altium, 3D printing, IPC certifications. Yet she was tremendously humble about her achievements through it all.

Here are some principles I gleaned from my conversation with Nancy Smith:

● “Make things that people can actually build.”

● “Learn by doing, not theorizing.”

● “Get close to the product. Touch it. Break it. Fix it.”

● “Stay curious. Stay kind.”

● “Fall in love with the process, not just the outcome.”

This is a north star in a sea of over-indexed analytics and half-finished dashboards. Good design isn’t just a result—it’s a way of seeing. And Nancy sees more clearly than most.

The Hardest Design Is Your Mindset

You know what struck me most from this conversation? Nancy never talked about "success."

We talk endlessly about engineering challenges like they’re the real mountain. They’re not. The biggest challenge is keeping your curiosity alive through the noise of deadlines, budgets, and “just make it work” pressure.

Nancy reminded me that the difference between burnout and brilliance isn’t raw talent. It’s attitude. Longevity in this field comes from one thing: never losing the spark that makes you care.

So the next time a design has you ready to throw your keyboard across the room, pause. Look for something in the problem that makes you curious. Because the board will fight you. The process will humble you. But if you can hold on to even a little joy, that’s when the work starts to sing.

She reminded me that being a good engineer isn’t about knowing the answer. It’s about knowing what questions to ask when the answer doesn’t make sense.

Your best design work comes when you’ve seen the build firsthand.

Speak up early. A little pushback now prevents months of rework.

Don’t wait for permission to learn something new.

Good engineering culture is built on trust and collaboration — not brilliance in isolation.

Real joy in engineering is possible. Look for it in the process.

Ask Yourself This:

When was the last time you touched the thing you’re designing? When did you last sit next to a test engineer and really listen? When did you last feel proud of a design—not because it passed review, but because it was well made?

Nancy’s trying to build things that work plain and simple. And maybe that’s what we need more of right now—thoughtful builders.

Hardware Rich Development is a series from Quilter.ai featuring the engineers, designers, and thinkers who are pushing hardware forward by getting closer to the work. If you want to be part of this conversation—or nominate someone who should—drop us a line.

Let’s make the industry a little sharper, a little braver, and a whole lot more hands-on.