Björn Manuel Hegelich on Dangerous Lasers, the Art of Letting Go, and Building the Next Collider by Hand

We hold the record for laser-accelerated electrons: 10.4 GeV from a 10 cm gas cell. That’s not theory. That’s a thing we built.

There’s a certain kind of engineer who is not content with incremental improvements but manifests an entirely new approach. Simply because it is possible. Physics will allow it. This new thing should exist.

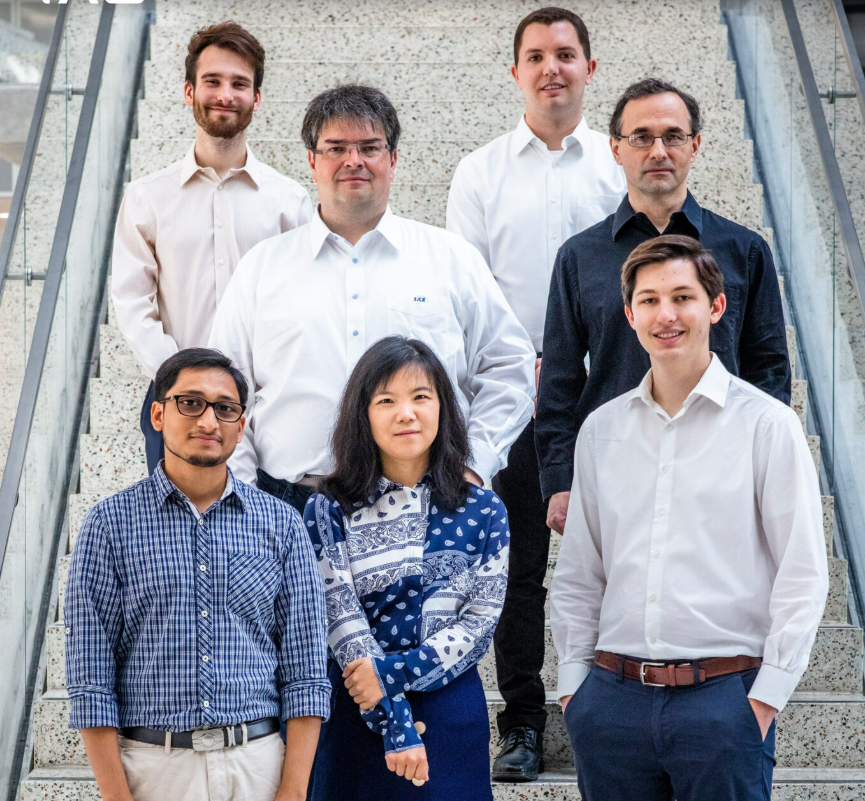

Björn Manuel Hegelich is one of those engineers. His team at TAU Systems is building ultra-compact laser-driven particle accelerators that challenge what we think is possible in physics infrastructure. These are not small upgrades. They’re redefinitions. Hundred-gigavolt-per-meter fields. High-energy electrons delivered from a system the size of a closet. Enough punch to simulate cosmic radiation or target a tumor with sub-millimeter precision.

But the thing that sticks with you about Björn is not the tech—it’s the time. The way he’s spent decades following a single idea, through national labs, academic tenure, a startup, and now, commercial hardware in the field. He’s a scientist who became a builder. A professor who became a founder. And he’s still learning how to let go of the work he used to do by hand.

Driving Deep, Technical Insight

In my experience, there is no replacement for truly understanding what you are building. Not in broad strokes, but at the level where you know how each part behaves, how it fails, and why it behaves the way it does. In laser-plasma physics, you are not skimming the surface of complexity. You are immersed in it. These systems are not forgiving. If you miss something important, you will see the consequences quickly.

Deep technical insight is not about theory for its own sake. It is about making things work when the margins are tight and the risks are real. When you are accelerating electrons to gigavolt energies in a 10-centimeter gas cell, you cannot afford hand-waving. Small misunderstandings do not lead to small problems. They lead to broken equipment, delayed experiments, and in some cases, serious safety issues.

When you understand something deeply, everything else becomes more focused. You make better decisions. You know what can be simplified and what cannot. You are not guessing. You are not covering for what you do not understand with extra layers of caution. You are working with intent.

There is also a kind of humility in this. Nature is precise. It will show you where your understanding falls short. If you are willing to look closely and keep learning, it will also show you how to make something truly useful.

That kind of insight is what allows you to build systems that push the edge of physics while still delivering value to the real world. It is not just helpful. It is necessary.

From Physics to Product

Björn’s journey started in Munich, where he did his PhD at LMU Munich and the Max Planck Institute for Quantum Optics. He was part of a small but growing field investigating whether laser light could be used to accelerate charged particles. At the time, it was considered ambitious—maybe even niche. He stuck with it anyway.

“When I started my PhD, this field was just sort of in its infancy,” he recalls. “We were trying to figure out how a very intense laser could accelerate particles… we learned more, and we showed that it could be done.”

That early work led to research positions at Los Alamos National Lab, where he ran a high-intensity laser group for nearly a decade. Then to UT Austin, where he led a research team for another ten years. Each step was another piece of proof that the science worked.

“We reached a point where we said: okay, this works. Now if we want to make it useful, it has to come out of the lab. It needs to become a tool.”

So he founded TAU Systems.

How a Laser Becomes an Accelerator

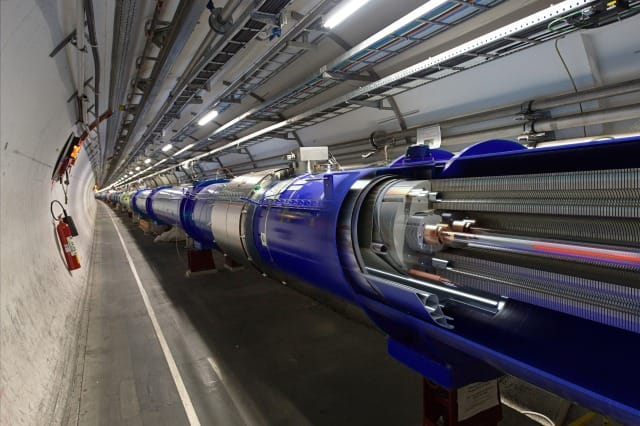

The underlying physics of TAU’s accelerator is elegant in its force. A high-power laser pulse enters a gas-filled chamber, turning it into plasma. That pulse creates a disturbance—like the wake behind a speedboat—and electrons surf the trailing wave. This “wakefield” acceleration allows electrons to reach gigavolt energies in centimeters rather than kilometers.

“In traditional metal accelerators, you're limited by electrical breakdown. You can't apply more than a certain field strength before you destroy your structure,” Björn explains. “But a plasma has no such limits. You can’t damage a plasma.”

The result: particle accelerators that are smaller, cheaper, and more adaptable. The kinds of systems that could eventually replace or supplement massive facilities like CERN or SLAC, and fit in a university basement or a regional hospital.

“Our goal is to take what used to be campus-sized machines and bring them into a size where they can be deployed widely—and used often.”

Practical Physics: From Space Chips to Medical Beams

TAU’s first commercial use case is radiation testing for electronics—especially those designed for space and high-radiation environments.

“Right now, if you want to test a chip for space, you’re fighting for beam time at three facilities in the U.S. They’re oversubscribed. NASA gets first priority. Everyone else gets what’s left.”

Björn’s accelerator offers a new approach. Rather than firing heavy ions, it uses tightly packed electron bunches to simulate the energy deposition of an ion in silicon.

“If you do it right, the chip doesn’t know the difference,” he says. “You don’t need to delid it or run overnight shifts at an old cyclotron. You can test more, earlier, and better.”

Another promising use case is very high energy electron therapy for cancer treatments. TAU is collaborating with MD Anderson Cancer Center to explore compact systems that can replace massive proton facilities.

“Proton centers cost hundreds of millions. If we can get comparable precision from a system that fits in a standard treatment room, that opens up access to a lot more patients.”

Building the Right Kind of Team

TAU isn’t a sprawling org with middle management and binders of process docs. It’s a tight, multidisciplinary team full of edge-case people. National lab veterans. Physics postdocs. Curious minds. People who are good at something very specific—and happy to wear gloves.

“I’ve always tried to hire people smarter than me,” Björn says. “Not in every direction. But each person should have their domain.”

His VP of Accelerators used to run a few-hundred-person division at Los Alamos. Now he leads a handful of engineers with the same seriousness and hands-on drive. Titles are fluid. People jump in where needed.

“We look for people who are experts but still willing to solder something if it needs to be done. You have to be flexible. Especially in a startup.”

But smart people come with strong opinions, and managing those dynamics can be tricky.

“Sometimes it’s like herding cats,” he admits. “You need a culture where people can speak up, ask questions, admit when they don’t know something. That starts at the top.”

Björn makes a point of showing his own ignorance when necessary. Asking questions is one of the most underrated engineering skills. It signals you are paying attention, that you care enough not to assume. In high-stakes systems, silence is more dangerous than ignorance. Clarity is not a luxury, it’s a requirement.

“I say, ‘I don’t understand this. Explain it to me again.’ That creates a space where others feel comfortable doing the same. And it saves us time, because silence slows everything down.” It gives others permission to admit gaps and move forward together. Good engineering depends on that kind of honesty. You can’t fix what no one is willing to name.

Time as the Real Constraint

As much as the technology at TAU stretches the boundaries of physics, the real challenge most weeks is time.

“I wish I had double the staff we have now. We have enough work for that. Everyone here is running full speed.”

Björn splits his week between technical oversight, investor relations, hiring, operations, and strategy. He color-codes his calendar—research, customers, team—to make sure his time tracks to what matters most.

“Every week I ask: am I actually spending time on the things that move the company forward?”

One of the hardest parts is saying no.

“There’s always something new that could make us 1 percent better. But you run out of hours. And you have to choose.”

TAU recently ran a 5 week long field experiment at the world’s most powerful laser, a 10-petawatt system in Romania. It was a milestone moment for the team. Björn didn’t go.

“I wanted to. But with everything going on at the company, I couldn’t justify the time. I know I have a team there that I trust to do the job. They don’t need me to micromanage them. I keep in touch remotely and concentrate on building the company. I pick my battles. (actually I broke down at the end and flew out for the last week, just to be with the team and to prepare future collaborations)”

Time, he says, is the invisible currency of leadership. The faster you realize what your hours are worth, the better your decisions become.

Letting Go of the Work You Love

For many technical founders, the hardest part of growth is stepping back from the hands-on work. Björn is no exception.

“I still love the research. I still love the experiments. But if I’m always the one making the decisions, we don’t scale.”

He talks about delegation not as a virtue but as a discipline—something you practice, often imperfectly.

“You start by doing something yourself because it has to get done. Then you do it again. And again. Eventually, you realize you’ve become a bottleneck.”

Handing off technical authority takes trust, clarity, and often some humility.

“Especially when it comes to research directions. Sometimes I see a team going down a path I know won’t work. And it’s hard not to jump in. But that’s part of learning to lead.”

Even still, he finds ways to stay close.

“We’re still doing cutting-edge experiments. I get updates daily. I give feedback. But I’m not driving every line of code or every alignment procedure anymore. I can’t be.”

The payoff is watching others rise. Former students take on design ownership. Early hires lead complex subsystems. His oldest son interns at the company. The youngest already wants to help.

“I’m still involved. But I’m not the center of everything anymore. That’s a good thing.”

Takeaways for Engineers, Founders, and Builders

Björn’s story is full of nuance—the patient push from theory to production, the balance between physics and pragmatism, the constant adjustment of how to spend time. But some takeaways rise to the surface.

1. Build from What You Know

TAU Systems wasn’t a pivot. It was the next logical step in a decades-long body of work. The science was ready. The need was clear. The founder was already deeply in it.

2. Hire Smart, Adaptable People

Expertise matters, but so does mindset. TAU hires for spike and flexibility. Deep skill in one area, plus the ability to contribute outside your lane.

3. Ask Questions Loudly

Smart teams move faster when they admit what they don’t know. Leadership sets the tone.

4. Know When to Let Go

If you do everything yourself, you’ll never get beyond what you personally control. Step back, even if it’s hard.

5. Respect the Physics—and the Clock

Some of the work will always be hard. But time doesn’t stretch. Trade wisely.

Closing Thoughts

Björn Manuel Hegelich didn’t start TAU Systems because it was trendy. He started it because the physics worked—and the world needed a way to use it. His story isn’t just about high-energy lasers and gigavolt gradients. It’s about investing in a long arc of work, surrounding yourself with the right people, and learning to build what only you can.

It’s also a reminder that technical leadership is not about having all the answers, or doing everything yourself. It’s about creating the environment where something ambitious, difficult, and worthwhile can finally get built.

“We’re just beginning,” he says. “There’s a lot more to build. And it’s not going to be easy. But it is going to be worth it.”